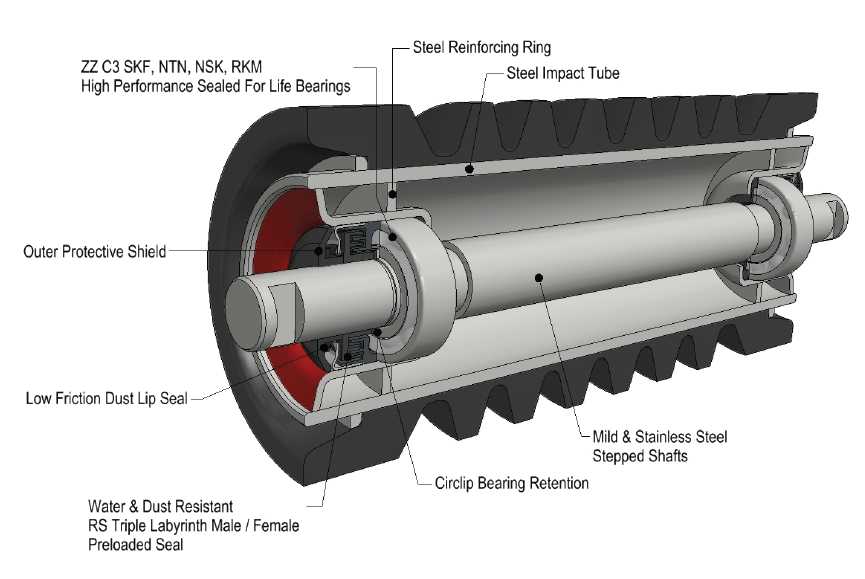

RKM impact rollers in general uses our RS steel roller and they are fitted with a variety of impact rings depending on the environment and impact load. These rollers are positioned on impact zones on the trough side of the conveyor.

Specification:

We provide a variety of impact rings such as:

- Rubber impact rings that comes in sections, upon which they are press fitted onto our steel rollers and locked in place using retainer rings.

- Hot bonded rubber impact rings. The steel rollers are placed in a steel mould and the impact rubbers moulded onto the steel rollers, providing a more secure bond.

- Hot bonded TPU impact rings. Similar process to hot bonded rubber impact rings, this uses high grade TPU material that provides improved oil resistance and thermal stability as compared to rubber. Other properties includes higher load bearing capability and high abrasion resistance.

Features:

- We also provide approved FRAS(Fire Resistance & Anti Static) rubber upon request.